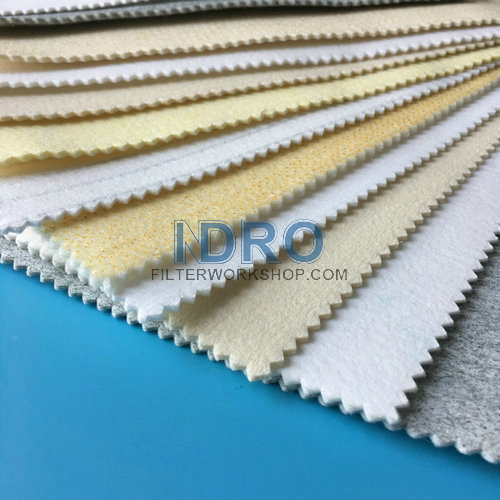

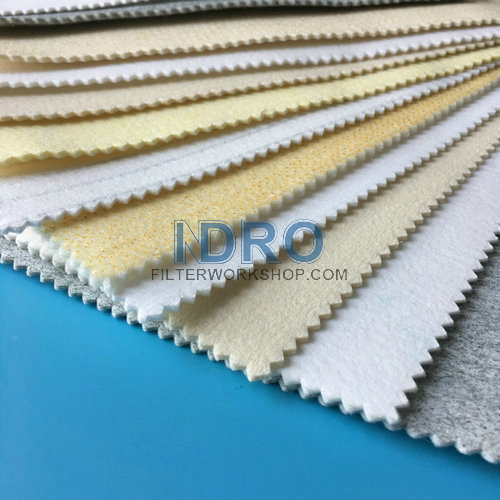

Filter fabric rolls are a fundamental component in industrial filtration systems, serving as the raw material for filter bags, cartridges, belts, and specialty filtration products. While they may appear simple at first glance, the

choice of fabric material and filtration grade has a direct impact on separation efficiency, pressure drop, service life, and overall system performance.

In industries such as dust collection, liquid filtration, food and beverage processing, chemicals, pharmaceuticals, mining, and wastewater treatment, understanding how filter fabric rolls are designed and classified is essential for selecting the right filtration solution.

This article explains the most common filter fabric materials, how filtration grades are defined, and how to match fabric properties with real-world operating conditions.

1. What Are Filter Fabric Rolls?

1. What Are Filter Fabric Rolls?

Filter fabric rolls are continuous lengths of woven, nonwoven, or felted textile media supplied in roll form. These fabrics are later cut, sewn, welded, or pleated into final filtration products such as:

- Dust collector filter bags

- Liquid filter bags

- Pleated filter cartridges

- Filter belts and sleeves

- Specialty industrial filters

Supplying filtration media in roll form allows manufacturers to control product dimensions, seam design, and surface treatments while maintaining consistent material quality across large production volumes.

2. Key Performance Factors of Filter Fabric Rolls

Before examining materials and grades, it is important to understand the core performance parameters that define filter fabric behavior:

- Filtration efficiency – the ability to capture particles of a given size

- Permeability (air or liquid flow rate) – resistance to flow through the fabric

- Mechanical strength – resistance to tearing, abrasion, and flex fatigue

- Chemical resistance – stability in acidic, alkaline, or solvent environments

- Thermal resistance – maximum continuous operating temperature

- Cleanability – how easily captured particles are released during cleaning

These factors are influenced by both

fiber material and

fabric construction.

3. Common Filter Fabric Materials

3.1 Polyester (PET)

Polyester is one of the most widely used filter fabric materials due to its balanced performance and cost efficiency.

Key characteristics:

- Continuous operating temperature up to ~130°C

- Good resistance to most acids

- Moderate resistance to alkalis

- High tensile strength and abrasion resistance

Typical applications:

- Industrial dust collection

- Cement and mineral processing

- Woodworking dust filters

- General liquid filtration

Polyester fabric rolls are commonly available in needle-felt and woven constructions and can be surface-treated to improve filtration efficiency and cleanability.

3.2 Polypropylene (PP)

Polypropylene is widely used in liquid filtration and low-temperature gas filtration applications.

Key characteristics:

- Excellent chemical resistance to acids and alkalis

- Low density and lightweight structure

- Continuous operating temperature up to ~90°C

- Hydrophobic nature

Typical applications:

- Water and wastewater filtration

- Chemical processing

- Food and beverage filtration

- Liquid filter bags and cartridges

PP filter fabric rolls are especially popular where chemical compatibility is more important than high temperature resistance.

3.3 Polyphenylene Sulfide (PPS)

PPS is a high-performance material designed for harsh industrial environments.

Key characteristics:

- Continuous operating temperature up to ~190°C

- Excellent resistance to acids and solvents

- Good resistance to hydrolysis

- Stable performance in high-temperature flue gas

Typical applications:

- Coal-fired power plants

- Waste incineration

- Boiler and flue gas filtration

- High-temperature dust collectors

PPS fabrics are often used where polyester would degrade too quickly.

3.4 Aramid (Nomex®)

Aramid fibers are known for their strength and heat resistance.

Key characteristics:

- Continuous operating temperature up to ~200°C

- Excellent mechanical strength

- Good resistance to abrasion

- Moderate chemical resistance

Typical applications:

- Asphalt plants

- Cement kilns

- High-temperature industrial dust collection

Aramid filter fabric rolls are selected when both temperature resistance and durability are required.

3.5 PTFE (Polytetrafluoroethylene)

PTFE represents the top tier of filter fabric materials.

Key characteristics:

- Continuous operating temperature up to ~260°C

- Exceptional chemical resistance

- Extremely low surface energy

- Excellent dust release properties

Typical applications:

- Chemical processing

- Pharmaceutical manufacturing

- High-corrosion environments

- Critical emission control systems

PTFE fabrics are often used as membranes laminated onto other substrates to enhance surface filtration performance.

4. Fabric Construction Types

4.1 Woven Fabrics

Woven fabrics are constructed by interlacing warp and weft yarns.

Advantages:

- High dimensional stability

- Precise pore size control

- Smooth surface

Limitations:

- Lower dust holding capacity

- Less suitable for fine particle filtration

Woven fabrics are commonly used in liquid filtration and low-dust-loading applications.

4.2 Needle-Felt Fabrics

Needle-felt fabrics are nonwoven materials formed by mechanically entangling fibers.

Advantages:

- High dust holding capacity

- Three-dimensional fiber structure

- Suitable for surface or depth filtration

Limitations:

- Higher pressure drop if not properly treated

Needle-felt rolls dominate industrial dust collection applications.

4.3 Melt-Blown and Spunbond Nonwovens

These fabrics are produced through polymer extrusion and fiber bonding processes.

Advantages:

- Fine fiber diameter

- High filtration efficiency

- Consistent quality

Typical applications:

- Cartridge filters

- Disposable filtration products

- Fine liquid filtration

5. Understanding Filtration Grades

Filtration grade defines the

particle size range that a fabric can effectively capture. It is typically expressed in microns (µm).

5.1 Nominal Filtration Rating

A nominal rating indicates that the fabric captures a certain percentage (often 85–90%) of particles at a given size.

Example:

A 10 µm nominal fabric captures most particles ≥10 µm.

5.2 Absolute Filtration Rating

An absolute rating indicates near-complete particle removal (typically ≥99.9%) at a specified size.

Absolute ratings are used in:

- Pharmaceutical filtration

- Food and beverage processing

- High-purity chemical applications

5.3 Surface vs. Depth Filtration Grades

- Surface filtration captures particles on the fabric surface, improving cleanability.

- Depth filtration captures particles throughout the fabric thickness, offering higher dirt-holding capacity.

Modern filter fabrics often combine both mechanisms through surface treatments or membrane laminations.

6. Surface Treatments and Enhancements

Filter fabric rolls can be enhanced with additional treatments to improve performance:

- Calendering – smooths the surface for better dust release

- Singed finish – removes loose fibers

- PTFE membrane lamination – improves fine particle capture

- Anti-static treatment – prevents spark discharge

- Oil and water repellent treatment – resists moisture and oil aerosols

These treatments significantly influence filtration efficiency and service life.

7. Matching Fabric Rolls to Application Requirements

Selecting the right filter fabric roll requires balancing:

- Operating temperature

- Chemical exposure

- Dust or liquid characteristics

- Required filtration efficiency

- Cleaning method

- Expected service life

No single fabric suits every application. A well-matched material and filtration grade ensures stable performance and reduced operating costs.

Conclusion

Filter fabric rolls are the foundation of effective filtration systems. Understanding the

common materials, construction methods, and filtration grades allows engineers and operators to make informed decisions that directly impact system efficiency, durability, and compliance with environmental standards.

By carefully selecting the appropriate fabric material and filtration grade—and applying the right surface treatments—industrial filtration systems can achieve reliable performance, extended service life, and optimized operating costs across a wide range of applications.