About Us

INDRO, a filtration group company with more than 20 years experiences in the industrial filtration field, is one of manufacturers and suppliers of a widely range of industrial filtration products and services relating to filtration technology.

With support of our own filtration technology team and skilled workers, we guarantee our filtration products with good and stable quality and delivery time.

We have two divisions: filter element division and filter machine division.

OUR FILTER ELEMENTS DIVISION-FILTER WORKSHOP:

Our filter elements division (filter workshop) makes and supply filter materials and rolls, dust collector and baghouse filter bags, filter bag cages, industrial liquid filtration bags, filter cartridges, filter housing/vessels and other accessories such as, fiber bag sewing thread, pulse jet valve, control board, air slide and etc.

We are using high class filter materials production equipments from Germany to produce filter rolls with excellent performance.

We custom make many kinds of polyester, polypropylene, acrylic, aramid, pps, ptfe, P84, fiberglass filter bags, filter bag cages, wire basket and related replacements which are widely used in dust collector bag house in the industry of steel, chemical, waste incineration, cement, construction material, thermoelectricity and other.

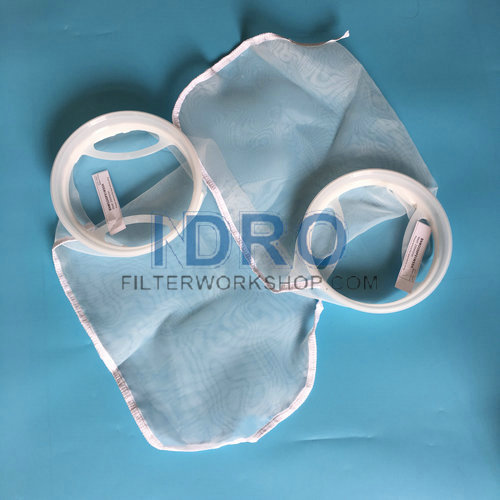

Our PE/PP/NOMEX/PTFE felt filter bags, PA/NMO/PE mesh filter bags and filter vessels are wildly used in electronics, semiconductor, chemical, pharmaceutical, food, beverages, advanced coatings & photo emulsions, paints & coatings, paper industry, automobile manufacturing, ink printing, resins, chemical processing, oil & gas, water treatment, aquarium filtration, swimming pool filtration and other industry.

OUR FILTER MACHINERY DIVISION-FILTER MACHINE:

Our filter machinery division is manufacturing and supplying filter equipments for making pleated filter cartridges, which include PP, PES, (Nylon) N6, N66, Fiberglass, PTFE membrane pleated filter cartridge production line, high flow pleated filter cartridge production line, pleated filter cartridge cap welders with hot plate welding and infra red (IR) welding system, filter cutter, middle seam welder and pleat makers, we supply automatic filter bag sewing machines and filter bag welding machines.

We service customers in the most diverse industrial branches- and this world-wide, such as North America, South America, European, South East Asia and other area etc.

With support of our own filtration technology team and skilled workers, we guarantee our filtration products with good and stable quality and delivery time.

We have two divisions: filter element division and filter machine division.

OUR FILTER ELEMENTS DIVISION-FILTER WORKSHOP:

Our filter elements division (filter workshop) makes and supply filter materials and rolls, dust collector and baghouse filter bags, filter bag cages, industrial liquid filtration bags, filter cartridges, filter housing/vessels and other accessories such as, fiber bag sewing thread, pulse jet valve, control board, air slide and etc.

We are using high class filter materials production equipments from Germany to produce filter rolls with excellent performance.

We custom make many kinds of polyester, polypropylene, acrylic, aramid, pps, ptfe, P84, fiberglass filter bags, filter bag cages, wire basket and related replacements which are widely used in dust collector bag house in the industry of steel, chemical, waste incineration, cement, construction material, thermoelectricity and other.

Our PE/PP/NOMEX/PTFE felt filter bags, PA/NMO/PE mesh filter bags and filter vessels are wildly used in electronics, semiconductor, chemical, pharmaceutical, food, beverages, advanced coatings & photo emulsions, paints & coatings, paper industry, automobile manufacturing, ink printing, resins, chemical processing, oil & gas, water treatment, aquarium filtration, swimming pool filtration and other industry.

OUR FILTER MACHINERY DIVISION-FILTER MACHINE:

Our filter machinery division is manufacturing and supplying filter equipments for making pleated filter cartridges, which include PP, PES, (Nylon) N6, N66, Fiberglass, PTFE membrane pleated filter cartridge production line, high flow pleated filter cartridge production line, pleated filter cartridge cap welders with hot plate welding and infra red (IR) welding system, filter cutter, middle seam welder and pleat makers, we supply automatic filter bag sewing machines and filter bag welding machines.

We service customers in the most diverse industrial branches- and this world-wide, such as North America, South America, European, South East Asia and other area etc.